CLAAS explains the Cow-er Station

Germany is currently home to around eleven million cattle. Some 3.8 million of these are dairy cows. In statistical terms, there are 66 cows for every 100 hectares of agricultural land. In practical terms, that means 66 unused power stations, discovered cattle farmer Detlev Blunk.

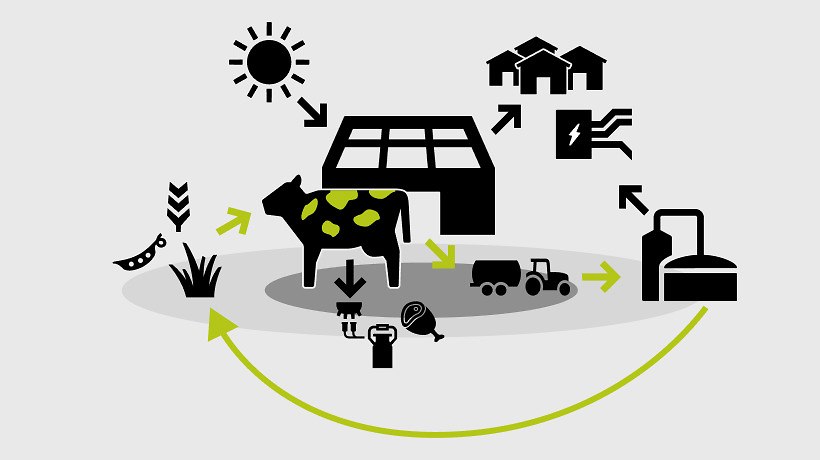

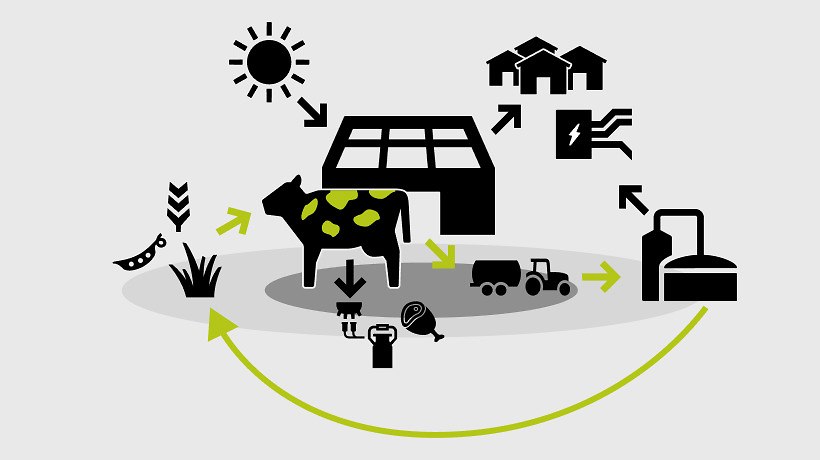

On his Hörnsee farm in Schleswig-Holstein, this farmer is adding his livestock to the cycle. Here’s an overview of his farm setup for all those for whom numbers speak louder than words:

The heart of the system: 400 cows

“Unlike poultry or pigs, the cattle are the only livestock that essentially turn grass directly into meat,” explains Blunk. Cattle use green land that is not used for arable farming. This reduces the use of imported soya-based feeds. One cow has a daily energy requirement of 37.7 megajoules. Everything that is fed above this amount is available for the cow to turn into milk. “That’s around 3.25 megajoules per litre of milk.” Alongside milk and meat, the cattle also produce slurry: around 40 m3 per day.

Heat: biogas plants produce 3.2 million kWh of heat each year

The biogas plant is fed with around 70% slurry and 30% renewable raw materials. The waste in the form of fermentation substrate provides available nutrients for plants. “It hardly smells at all – the neighbours are pleased about that.” They’re also pleased that the two combined heat and power plants (CHPs) and the (local) district heating network provide heat to some 220 homes in the surrounding area. The combined installed power of the two CHPs is 1,960 kW – so high that power and heat from the flexible power station is only generated on demand. “In total, we produce 3.2 million kWh of heat each year,” says the cattle farmer. Of that, around 1 million kWh are used on the farm itself. The rest goes to the nearby homes, saving an estimated 200,000 litres of heating oil. In addition, the two CHPs produce an average of 400 kW of regenerative power per hour, with the surplus being fed back into the public electricity supply grid.

Fertiliser: 20 m³ per hectare

The biogas plant produces a fermentation substrate that is useful to plants, bringing the nitrogen (N) that they need for growth to their roots more effectively. This enables the farmer to replace mineral fertilisers, which are often imported from other countries, with this homemade fermentation substrate. “To be honest, I need a bigger biogas plant and more livestock to allow me to use even less mineral fertiliser,” says Blunk, with an eye to a more complete cycle. “We then apply the fermentation substrate immediately with drag hoses, working on the precision farming principle, with hardly any overlaps,” explains the farmer.

Power: photovoltaic system with peak output of 180 kW

Above the cattle barn, a modern photovoltaic system with an output of 180 kWp converts sunlight into electricity. For those who don’t yet have a PV system on their roof, kWp stands for kilowatt peak and is a unit used to describe the performance of photovoltaic systems. It is the maximum output that a solar system can generate under ideal conditions. In real terms, on the Schleswig-Holstein farm this means that “Combined with the biogas plant, we produce a total of 3.6 million kWh of electricity per year,” explains the farmer. That provides the farm with electricity and the surplus is exported to the local energy provider’s supply network.

The future: N not m³

New approaches to the cycle are needed in agriculture, whether in terms of cultivation or technology, says Blunk. It doesn’t always work: the farmer planted peas on ten hectares as feed for the cattle. They were intended to reduce soya imports, but “it was too dry that year, so they didn’t pay off,” he says. He is more hopeful about his near infrared spectroscopy (NIRS) sensors. These sensors measure the current nitrogen content at the slurry outlet – and the farmer just needs to apply enough to meet the plants’ nitrogen requirements. Blunk is sure that soon the word on his farm will no longer be, “Go and spread 20 m3 of slurry!”, but instead, “Go and spread 70 kg of nitrogen!”.